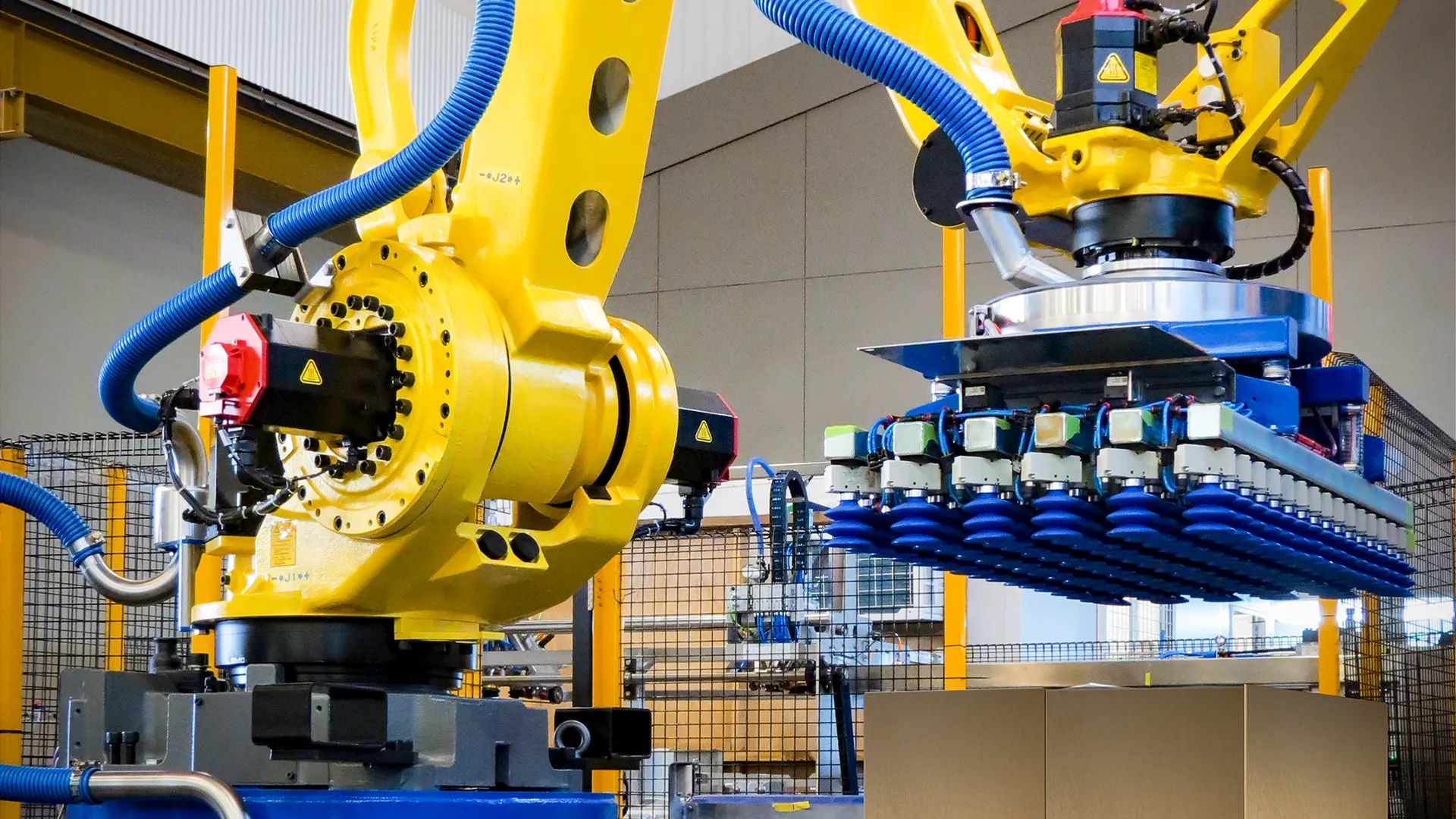

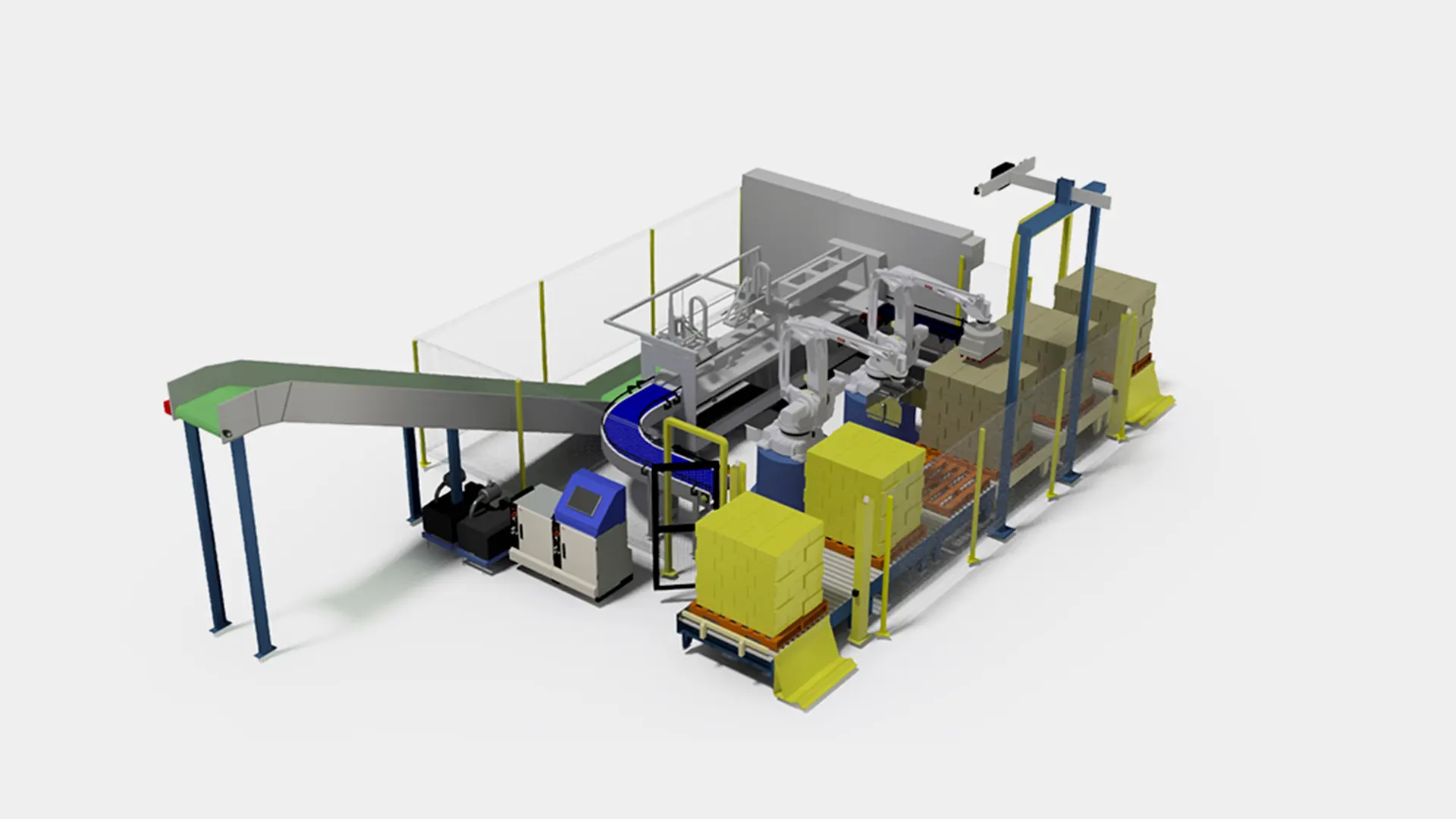

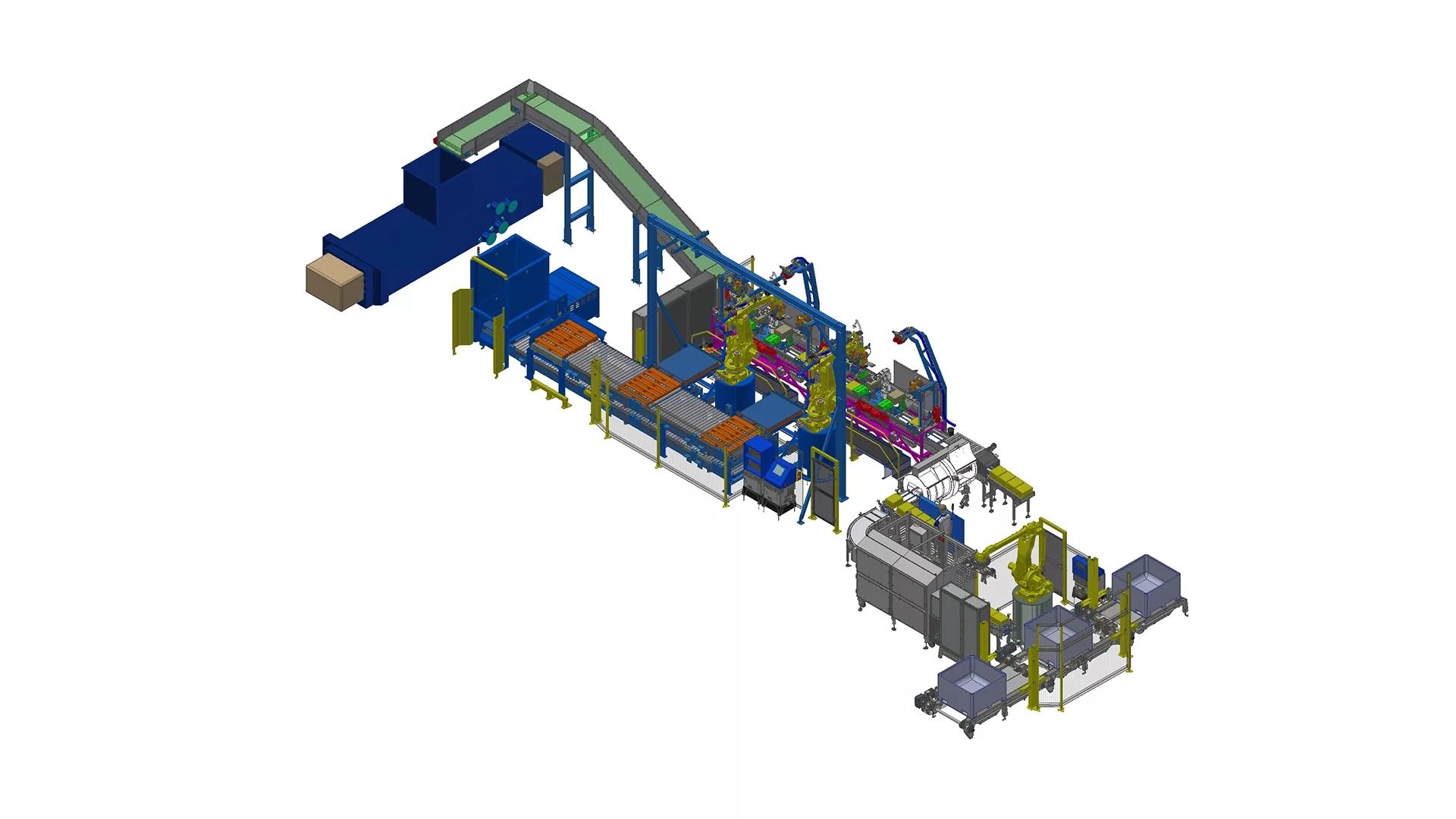

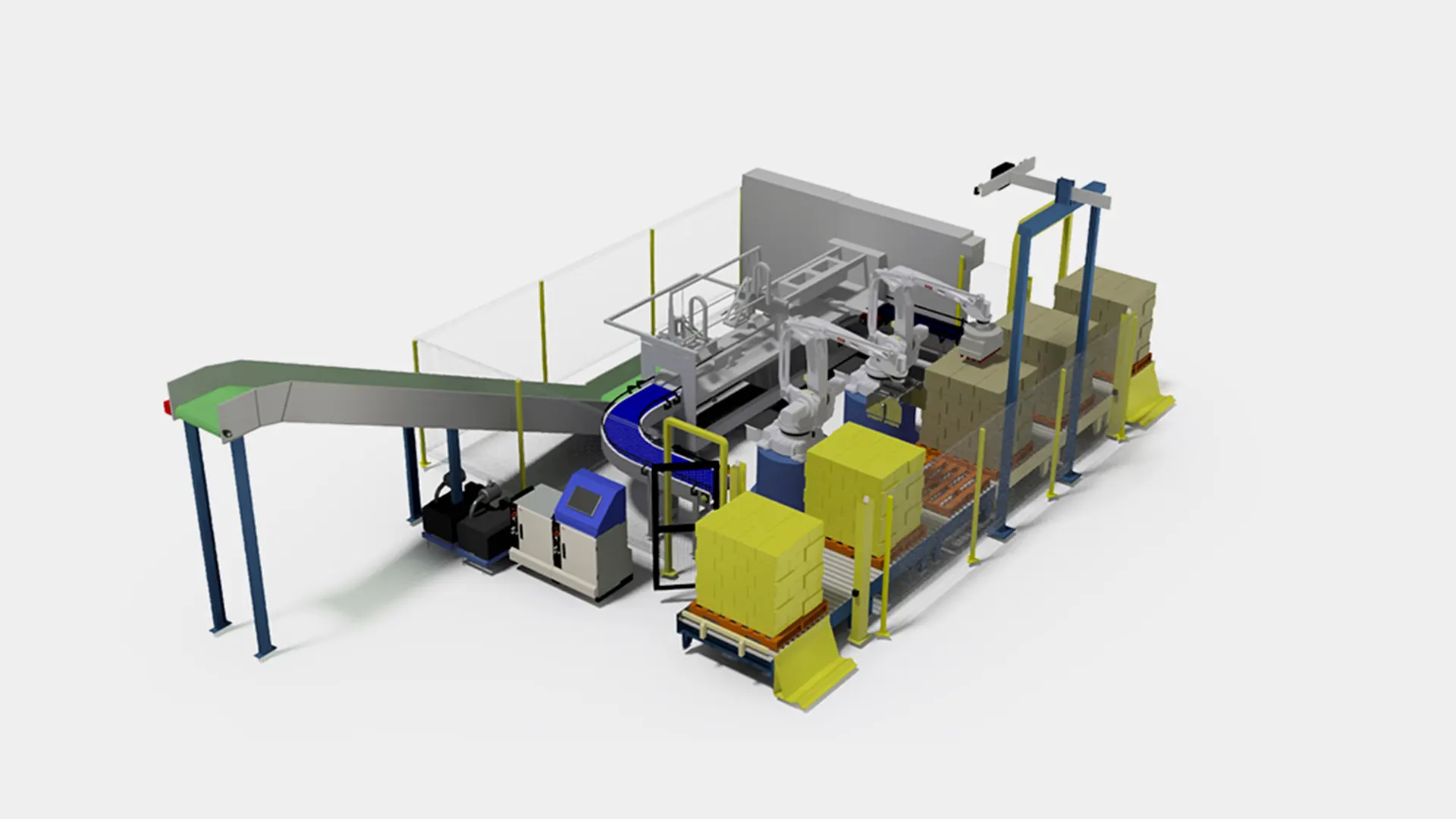

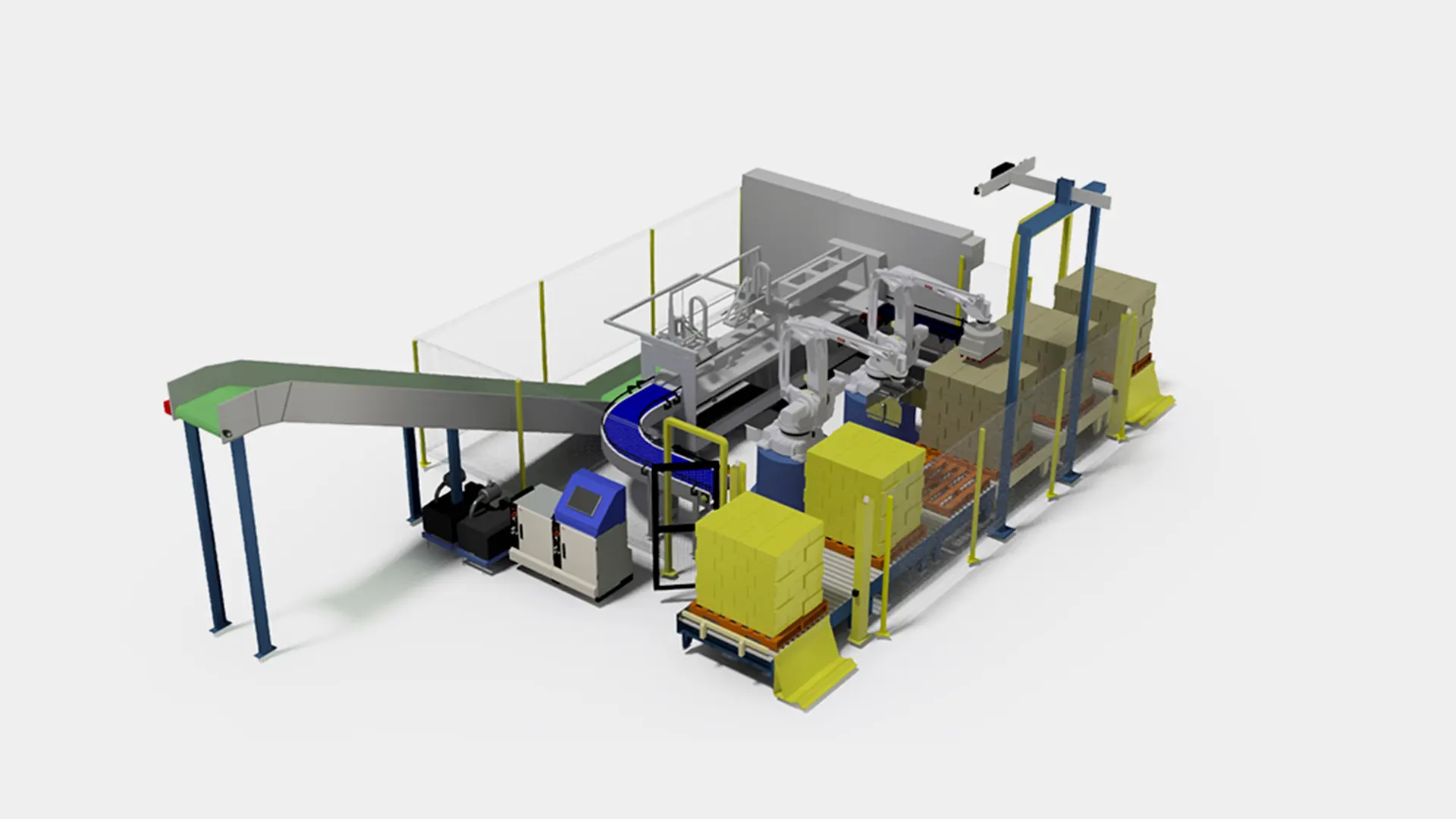

Also known as the DDRP-40, the De-palletise, De-carton, Re-palletise system removes 40lb boxes from a pallet, removes the cartons and re-palletises the bagged blocks again at a rate of up to 16 blocks per minute.

It features the unique, H&C-developed 3 Dimensional De-palletising (3DD) vision system, which detects boxes of product in any configuration and enables optimal pick-up to deliver faster and more reliable de-palletising.

The DDRP-40 uses MHM’s superior cutting and carton removal technology to provide unparalleled reliability. It will safely remove the outer packaging, presenting an undamaged, wrapped block every time. With a proven track record in the industry, this is the best de-cartoning system available in the market today.

Benefits

- Improves line efficiency 24/7

- Reduced labour – allows staff to be re-deployed to higher value work

- Elimination of manual handling and the associated risk of injury to staff

- Removed risk of product contamination

- Reduced risk of accidentally cutting the bag

- Waste corrugate managed effectively

- Best in class footprint

H&C

Recognised as a world leader in automated reverse packaging and product handling systems, we acquired Haden & Custance (H&C) in 2016.

While many other companies provide solutions to putting product into packaging, we are specialists in removing packaging from product ready for further processing.