Industries

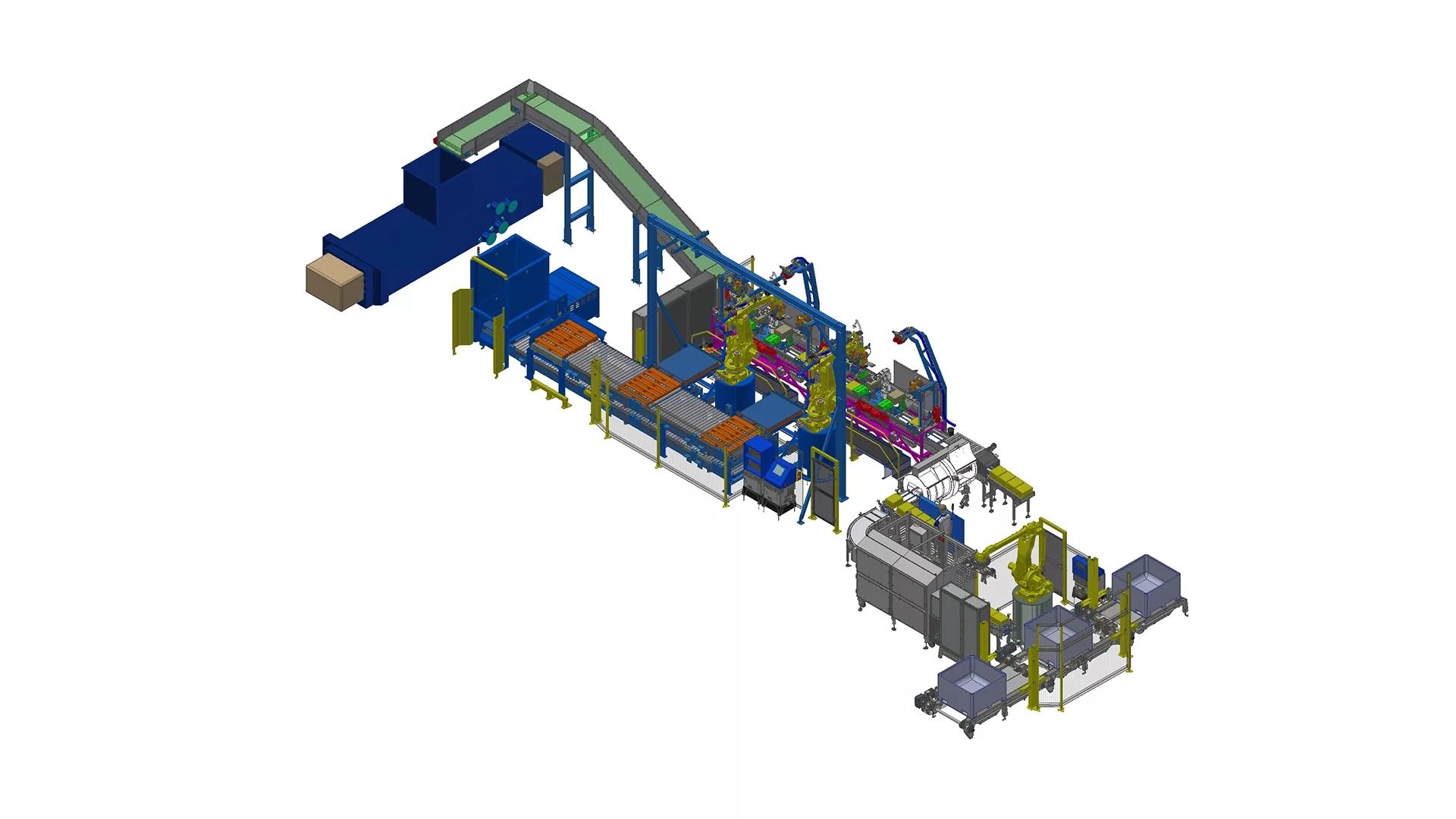

MHM Automation is constantly innovating to develop solutions that can enhance efficiency and drive growth in your business.

Learn more about our solutions for the following industry sectors.

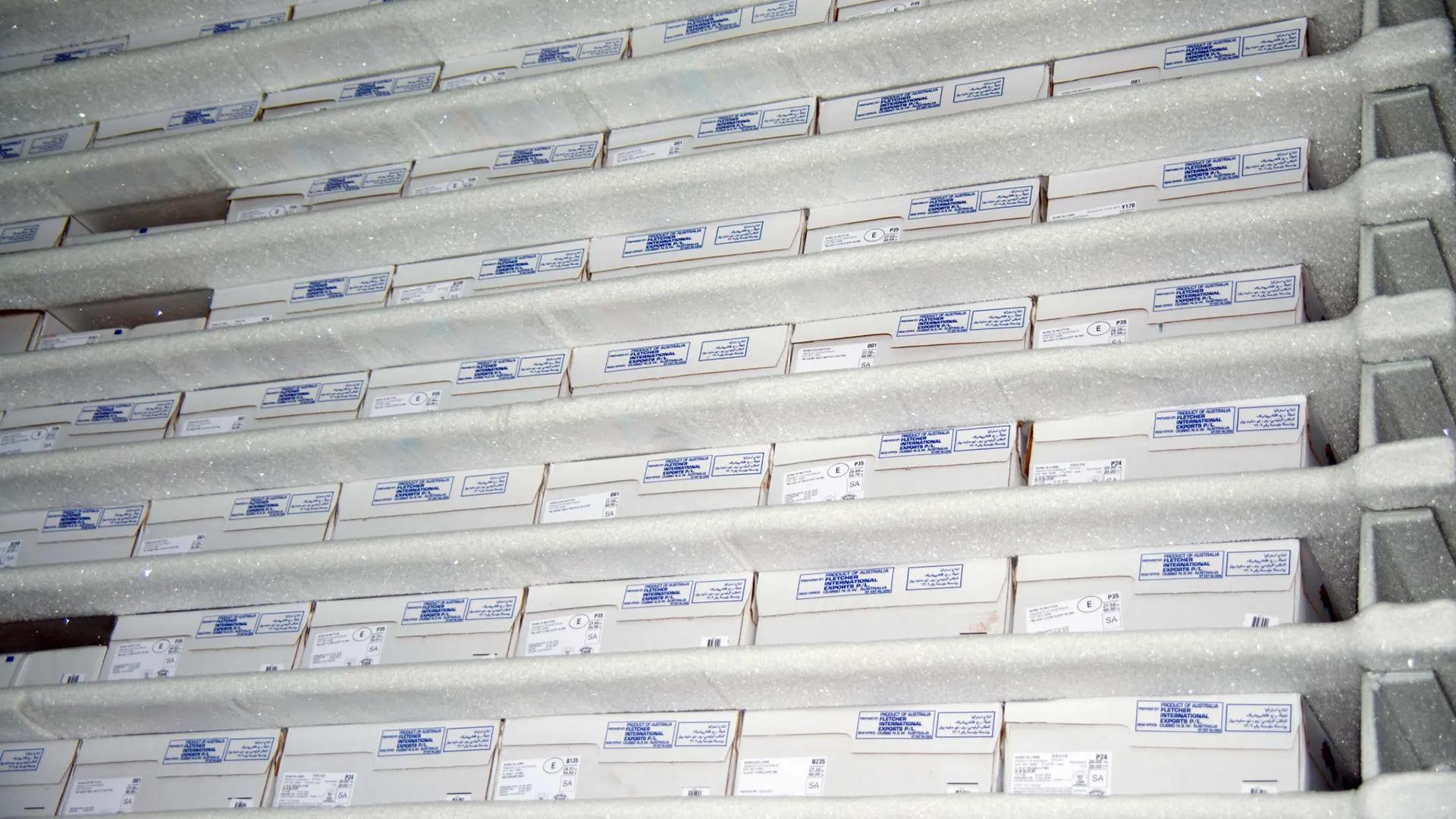

Meat

Cheese & Dairy

Food & Beverage

Fruit & Vegetables

Timber & Sawmilling

Grain & Feed

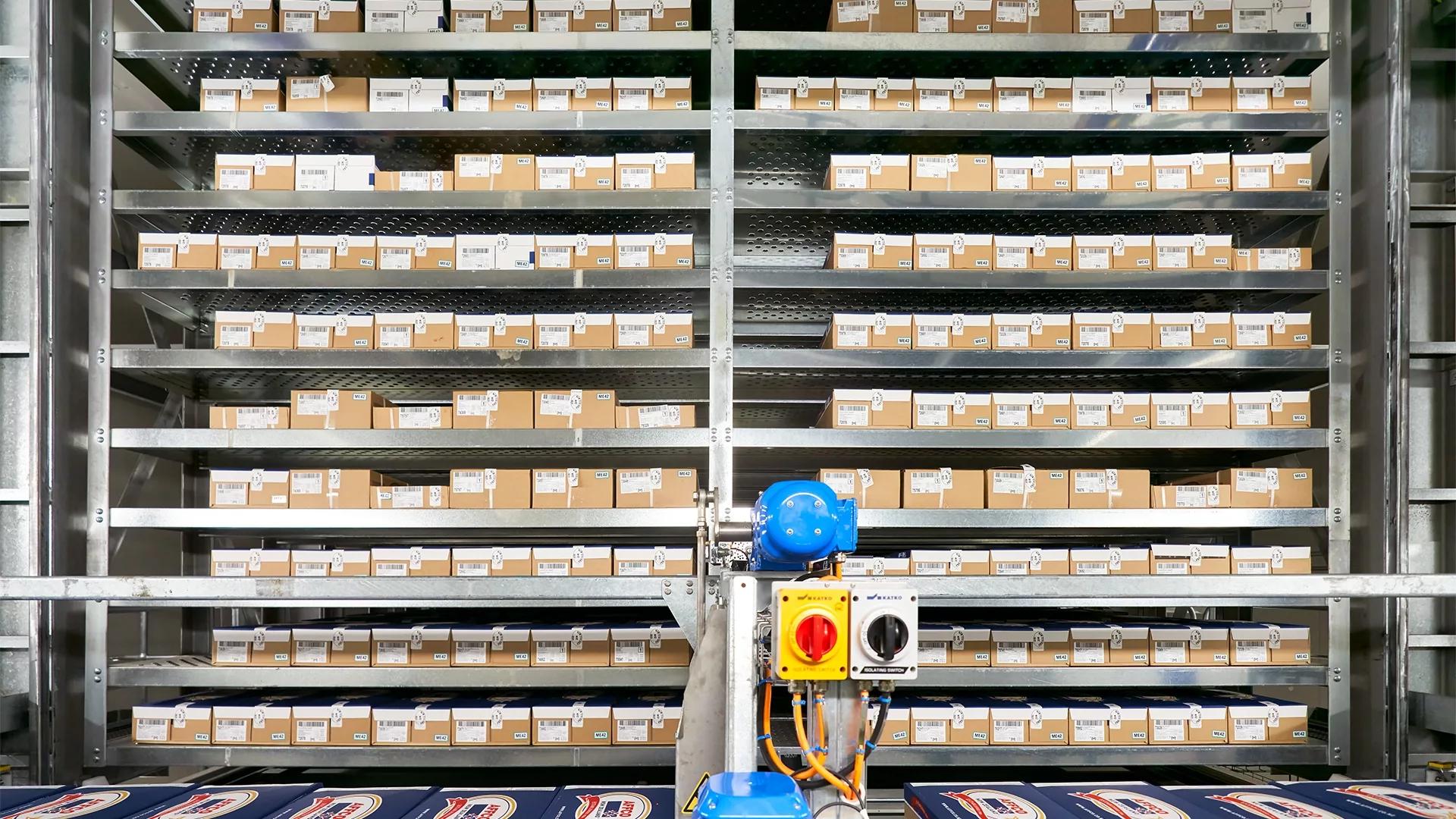

Logistics

Antarctica

Industrial