MHM Automation provides a broad range of technologies and solutions for food and beverage processing.

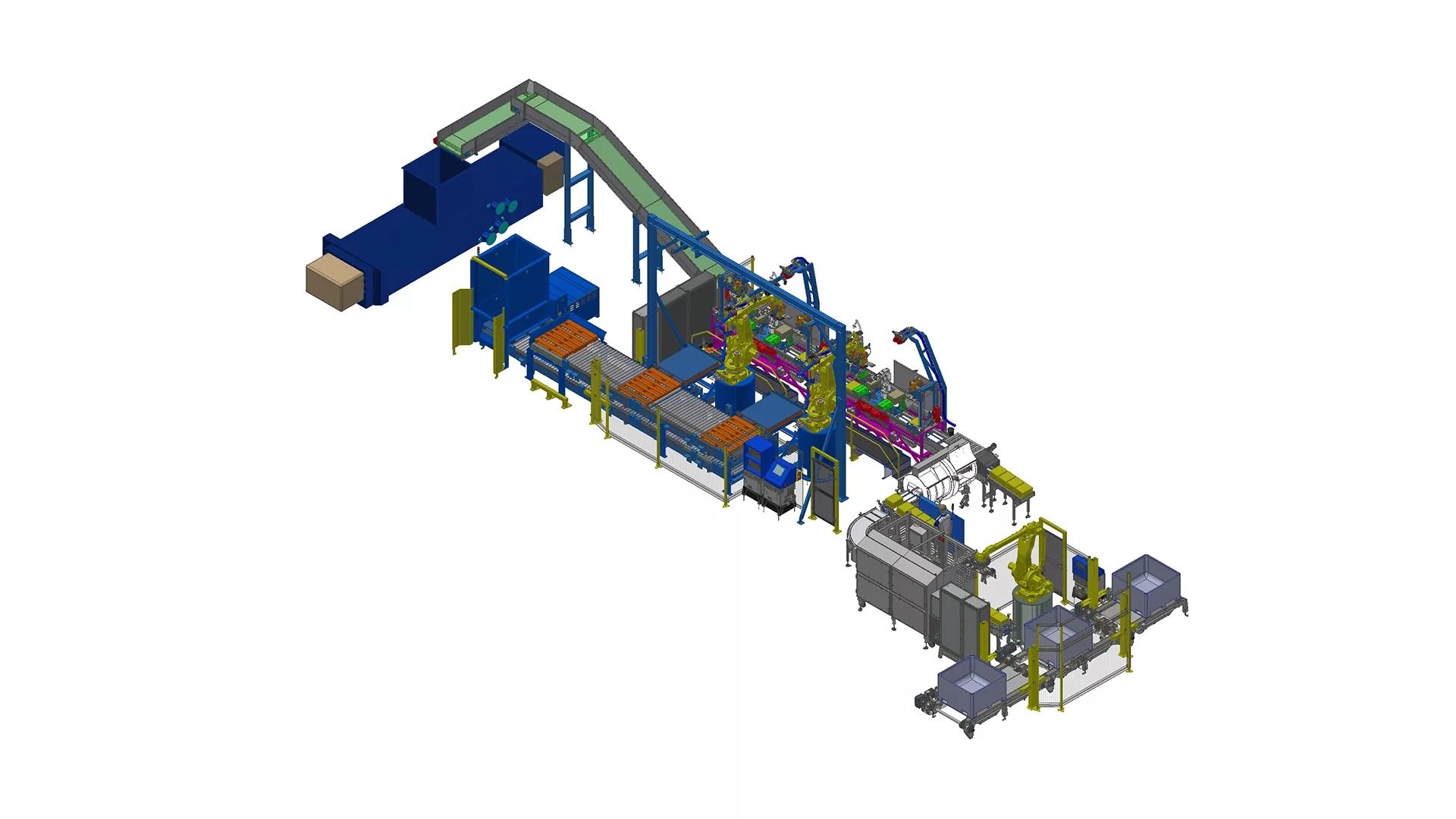

At the front end of operations, our solutions span transportation, storage and handling of liquids and powders, de-palletising, de-cartoning, conveying, sorting and recipe management.

Our processing equipment includes vessels for fermentation, cooking, mixing and cooling, as well as heat sources to fuel factory operations.

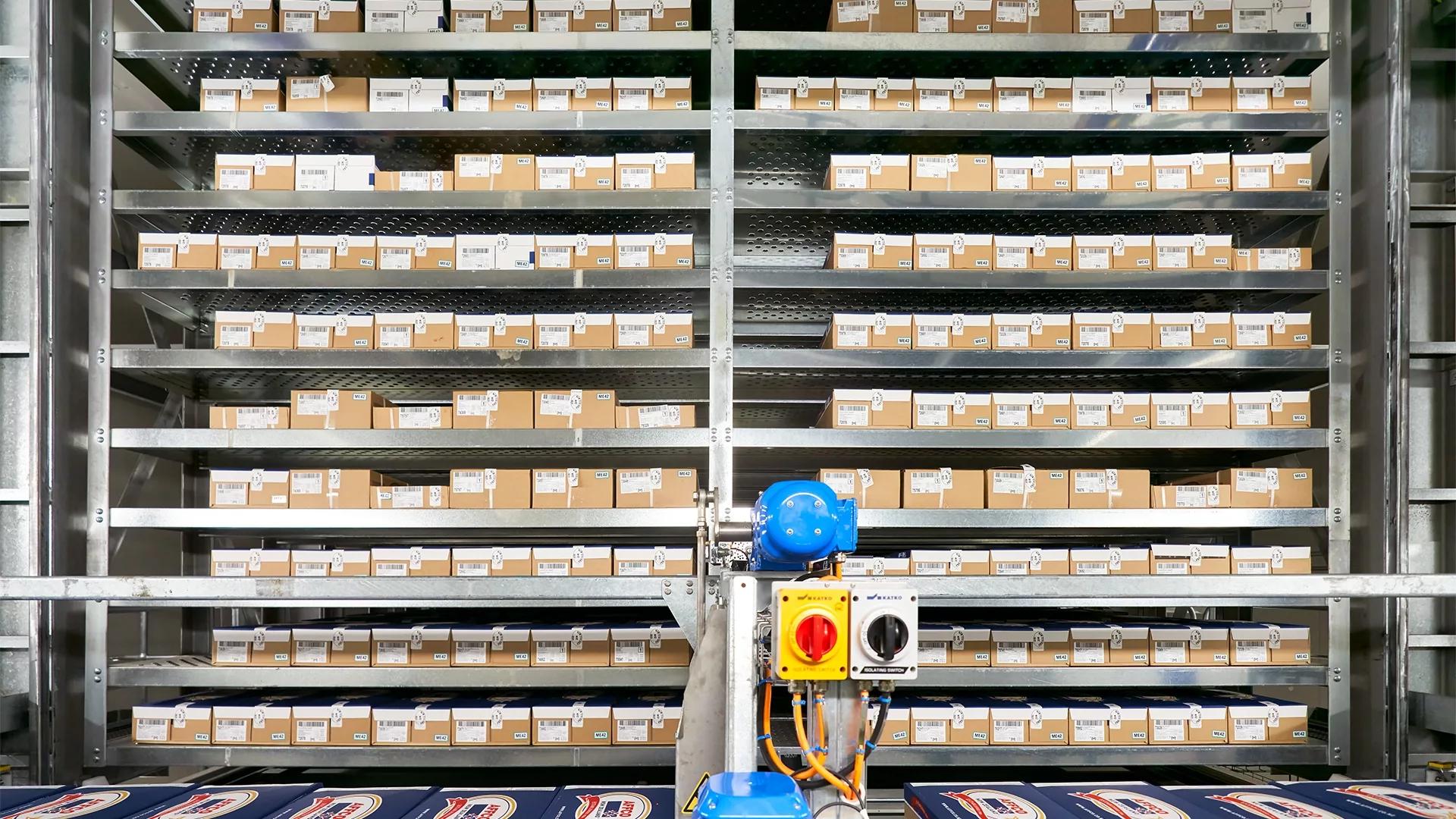

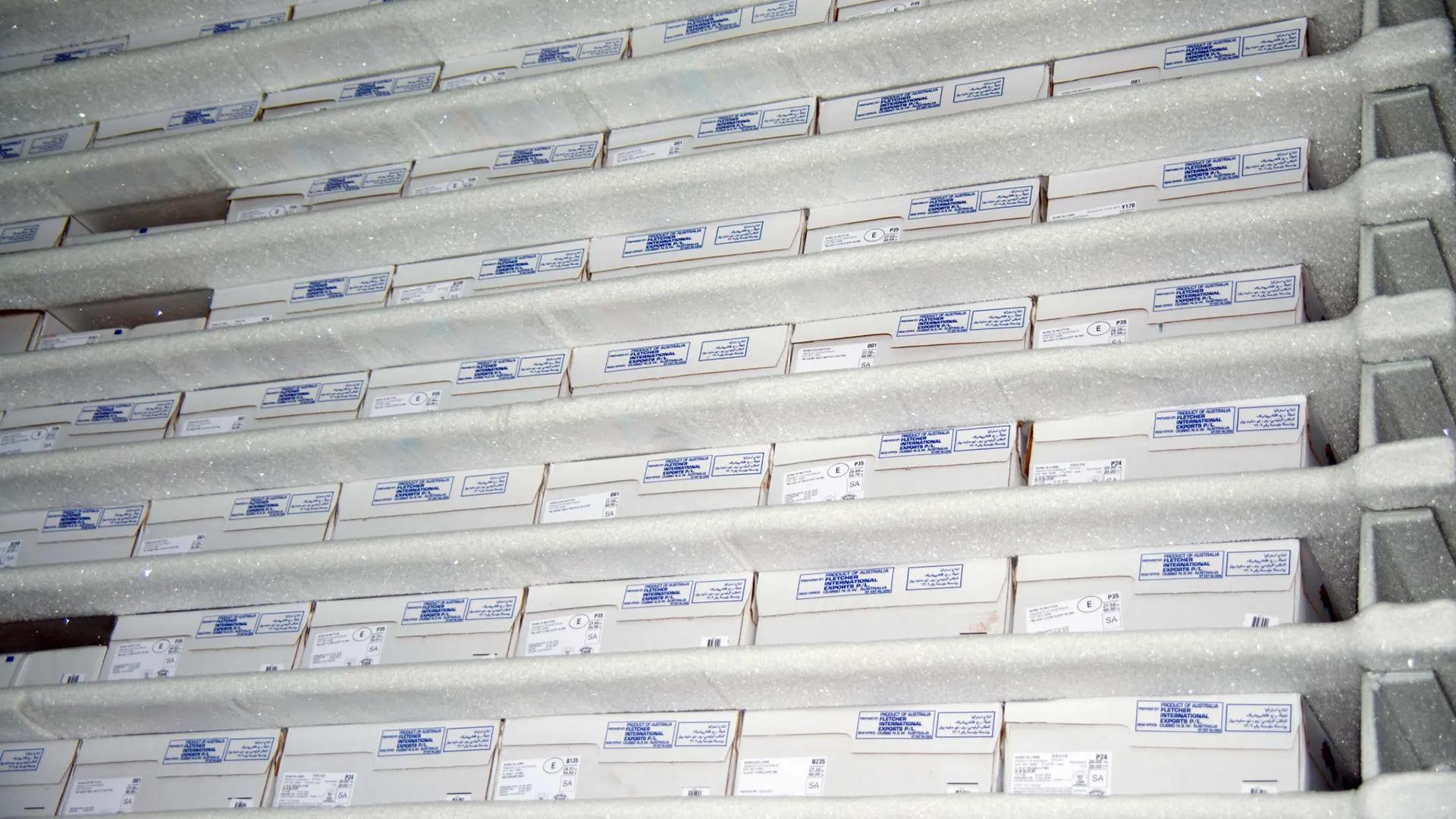

At the back end of operations, we provide fully integrated packaging, conveying, chilling and freezing, sorting, palletising and storage systems.

Our technologies are recognised by food processors for their reliability and simplicity of operation.